Choose

wire EDM when you need:

- accurate

parts

- fine

finishes

- burr-free

parts

- perpendicular

cut surfaces

- accurate

side tapers

- moderate

quantities of thin flat parts ( tens, hundreds or low thousands)

- accurate

relation to other features

- parts

that are thicker than their width

- minimum

heat affected zone

- fragile

delicate parts

- small

parts

- frequent

design changes

Laser

or waterjet is cheaper when you can accept:

- Open

tolerances and rougher finishes

- Non-perpendicular

cut surfaces

- Larger

internal corner radii

Plasma

or oxy-fuel works when you can live with :

- Precision

measured with a tape measure

- Large

heat affected zone

- Dross,

scale, edge gouges and other gross imperfections

Punching

is best when you need very high volumes or:

- Drawn,

stamped or bent features on the part.

- Embossing

or marking on the part

|

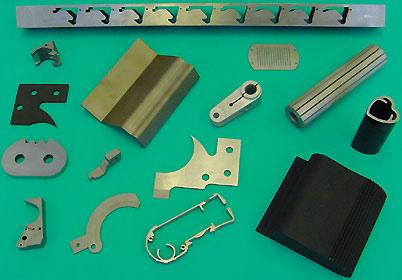

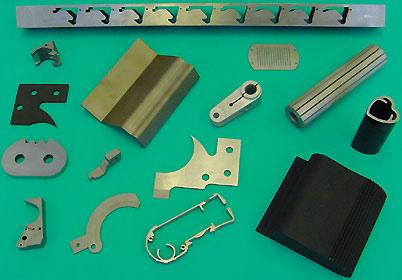

Click

to enlarge |