| Home | About Vancouver Wire EDM | Our Capabilities | Our Machining Services | Tech Tips | Request a Quote |

|

Vancouver Wire EDM | |||||

Vancouver Tel: 604-899-8977 Fax: 604-899-0959

|

Tiny or large, Vancouver Wire EDM will work with you to create the short run or large run custom tools to run your jobs efficiently.

Tiny custom reamer tool |

1" diam Custom Carbide End Mill |

What is a tool insert? A tool insert refers to a cutting tool where the cutting edge consists of a separate piece of material clamped or fastened to the tool body. Inserts are frequently used in woodworking and metal working. Inserts allow the cutting edge of a tool to be easily replaced in a less expensive tool holder. Many tool inserts are indexible so that they can be rotated, allowing a fresh cutting edge to be presented without resharpening the tool. In serts made with wire EDM can have complex profiles, allowing an operator to cut a complex shape in a single operation

|

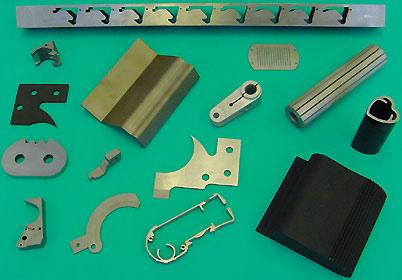

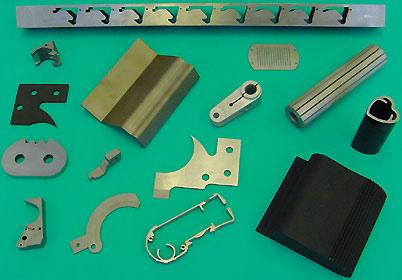

Custom Tool Inserts |

|

Designing a custom insert and custom tool case study: Ticatinny Rail Tool The right custom tool or custom insert can greatly reduce machining time by eliminating operations needed to produce a part or a feature. The image below shows three examples of custom inserts and custom holders to create standard Picatinny rail. Figure 1 Custom Carbide End Mill-- uses a carbide end mill, into which we EDM the shape of the feature. Least expensive method. The tool is cheaper but it will require sharpening or replacing as a unit. Ideal for short runs. Figure 2 Modified face mill with custom inserts-- uses a modified face mill in conjunction with custom inserts. Great for larger runs of parts, next cheapest: as one can use a standard face mill with some modifications, and replace custom insert as it wears out. Cost of inserts is cheaper than replacing end mill, as in figure 1 above. Figure 3 Custom Tool Holder with standard inserts -- Uses inexpensive standard inserts in a custom tool holder. This is the most expensive method as it relies on a custom tool holder, but the best option for large runs of parts as it allows for the use of off the shelf inserts. Each of these methods allow for increased production as the custom tools cut more surfaces at the same time. If you need help deciding what custom tool is best for you, we can help. Contact us with your custom tool design ideas or questions. info@vancouverwireedm.com

|

||

| ©2012Vancouver Wire EDM | Home • About Us • Capabilities • Wire EDM Info • Products |